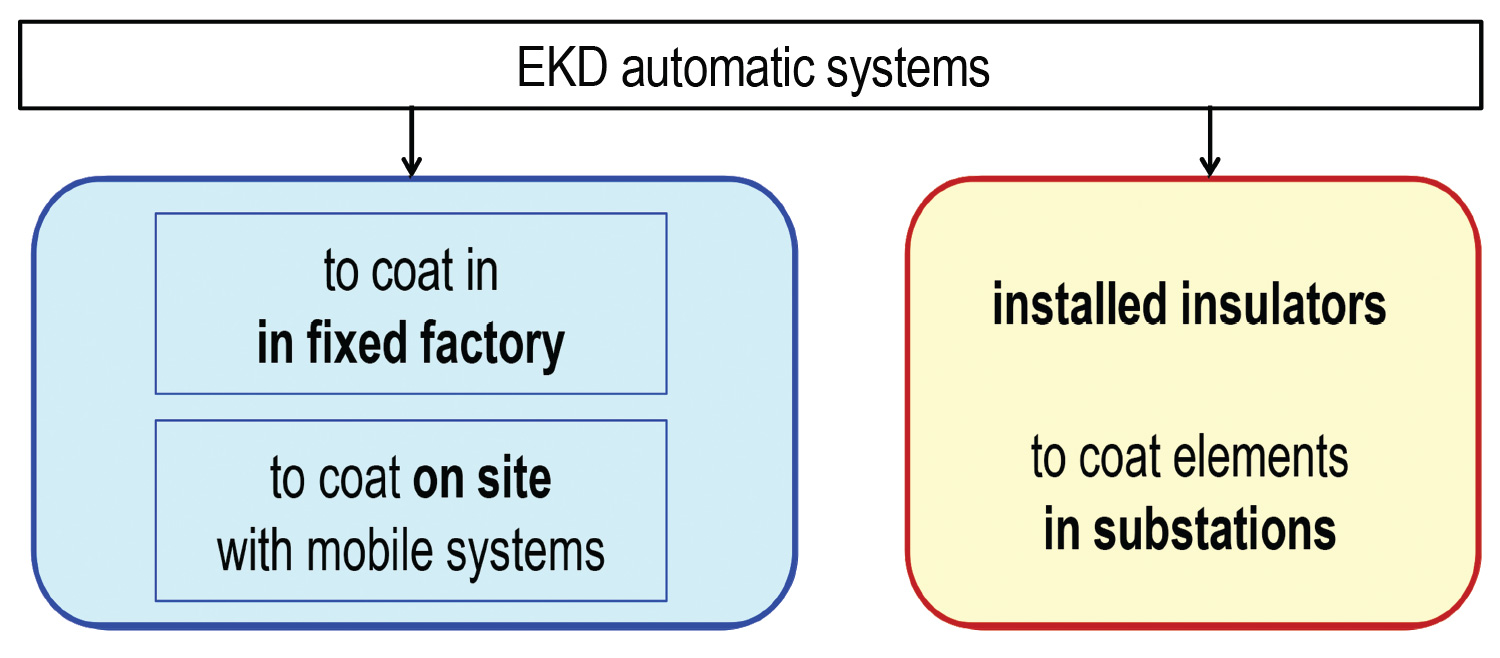

The Coating Division boasts twenty years of experience in the coating of high voltage electrical insulators. In order to meet the stringent specifications of the main world utilities for the production and distribution of electricity and making use of the collaboration of the Engineering and Manufacturing divisions, EKD has studied and realized automatic systems for coating with RTV silicone in situ and in factory.

In order to improve the quality of the coating, made on suspended and substation insulators, EKD is committed to the Research and Development of innovative and avant-garde solutions able to guarantee: high safety standards, reduced lead-times and an ever-better quality of product. This activity sees the participation of the Company in international technical committees, sector symposia and working groups.

Since 2004, it is estimated that EKD has coated in factory approximately 30% of the suspended high voltage insulators installed worldwide.

The coated isolators are installed in over 50 countries and mainly in Italy and South America. EKD is recognized as a reference in the sector and new projects are in progress for the coating of insulators at the installation sites with the help of mobile or fixed systems.

For several years EKD has been carrying out the silicone coating of elements of substations located in aggressive environments, where continuous maintenance interventions and consequent interruptions in the electricity distribution are required. Our automatic solutions allow you to apply the RTV silicone in the factory and in situ (on installed elements) with a significant reduction in waste and environmental impact and guaranteeing the highest quality standards.

The combination of Coating, Engineering, Manufacturing and Research & Development activities has allowed EKD to develop automatic systems capable of:

- Homogeneously apply any type of RTV Silicone, ensuring high process repeatability;

- Reduce the environmental impact and increase worker safety;

- Meet the strictest delivery times.

All solutions are made on the basis of customer specifications and internal procedures starting from the characteristics of the coating to the packaging.

In the last fifteen years EKD has developed mobile and fixed automatic systems that allow you to work line and substation insulators.

Based on the experience gained at the start of the business, in which the application of the silicone coating was completely manual, EKD has studied and created automatic systems that allow to drastically reduce waste, improve product quality and minimize environmental impact, ensuring the safety of workers. Our systems are constantly evolving and guarantee the highest product quality in compliance with the most stringent customer specifications.

the future for others is a past that we have already experienced…